Welcome guest blogger Katherine back to LoveintheD! To read her first guest post, click here. Curious about how Katherine made her own wedding dress for her Detroit wedding? Read on for her dress story!

When I told people about my intentions to make my own wedding dress, despite never having made any kind of dress ever in my life, they thought I was a little nuts. They said totally logical things like “I would be scared!” and “what will you do if it doesn’t work?” and “that sounds stressful and complicated!”

“I just don’t want you to be in a panic a week before the wedding because you have nothing to wear…” said my sweet, and extremely reasonable, fiancee.

• •

Despite it being a very large project, I can honestly say that the wedding dress was the least stressful of my many DIY projects for the wedding (aside: just because you’ve seen other people screen print, that does not mean you are ready to screen print your wedding invites). One of the reasons it was so low-stress is that I started very early. Another is that my wedding dress was never going to be exactly “traditional.” So go ahead and get that big white cake of a dress out of your head right now.

I actually didn’t set out to make my own wedding dress, and first found a seller on Etsy who made dresses that I thought might fit my criteria (eco-friendly, not white, dripping with sentimentality, LACE, budget-friendly) but one night while pursuing my options and dreaming I suddenly thought: “Wait. I can do that!”

Left: Dress base made of a slip and a loose skirt dyed green / Right: Early sample layout for dress that was ultimately abandoned as too busy

My dress (much like the ones I liked on Etsy) uses a slip as a base, which eliminated a lot (though not all) of the complicated fitting process. I also relied heavily on trusted friends with more experience than me to consult me. Garment creation is often more complicated than it looks on the outside, so it was great to be able to call friends and ask: “Will this work?” Sometimes, the answer was: “Not exactly…” and I had to modify my plan slightly.

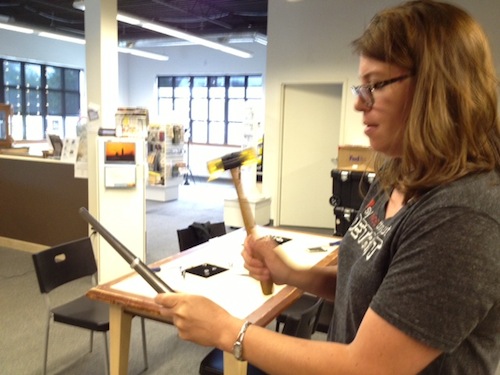

I did not use a pattern. Instead, I collected the pieces (shout out to Amy at Smallcraft for helping me get lace!) the dress would be made of and worked on the layout by pinning them together over and over again.

By far the most tedious portion was the lace sewing. Most lace needs to be sewn by hand in order to avoid unattractive bunching. I actually love hand-sewing, so this wasn’t a huge problem for me. I also found that a lot of wedding planning feels rushed, so it was great (for me) to have some forced downtime making slow and steady progress. It felt very romantic! However, if you are thinking of doing this yourself, be forewarned that I probably clocked at least 50 hours with a needle and thread in my hand.

My finished dress pictured with my partner Chelsea’s dress

Readers: Have you ever sewn your own clothing? Would you consider making your own wedding dress?